Insuline low voltage conductor shrouding has been designed to help electrical utility companies meet the onerous demands of ESQCR regulations and in particular the safe distance of bare conductors in proximity to buildings, structures and trees.

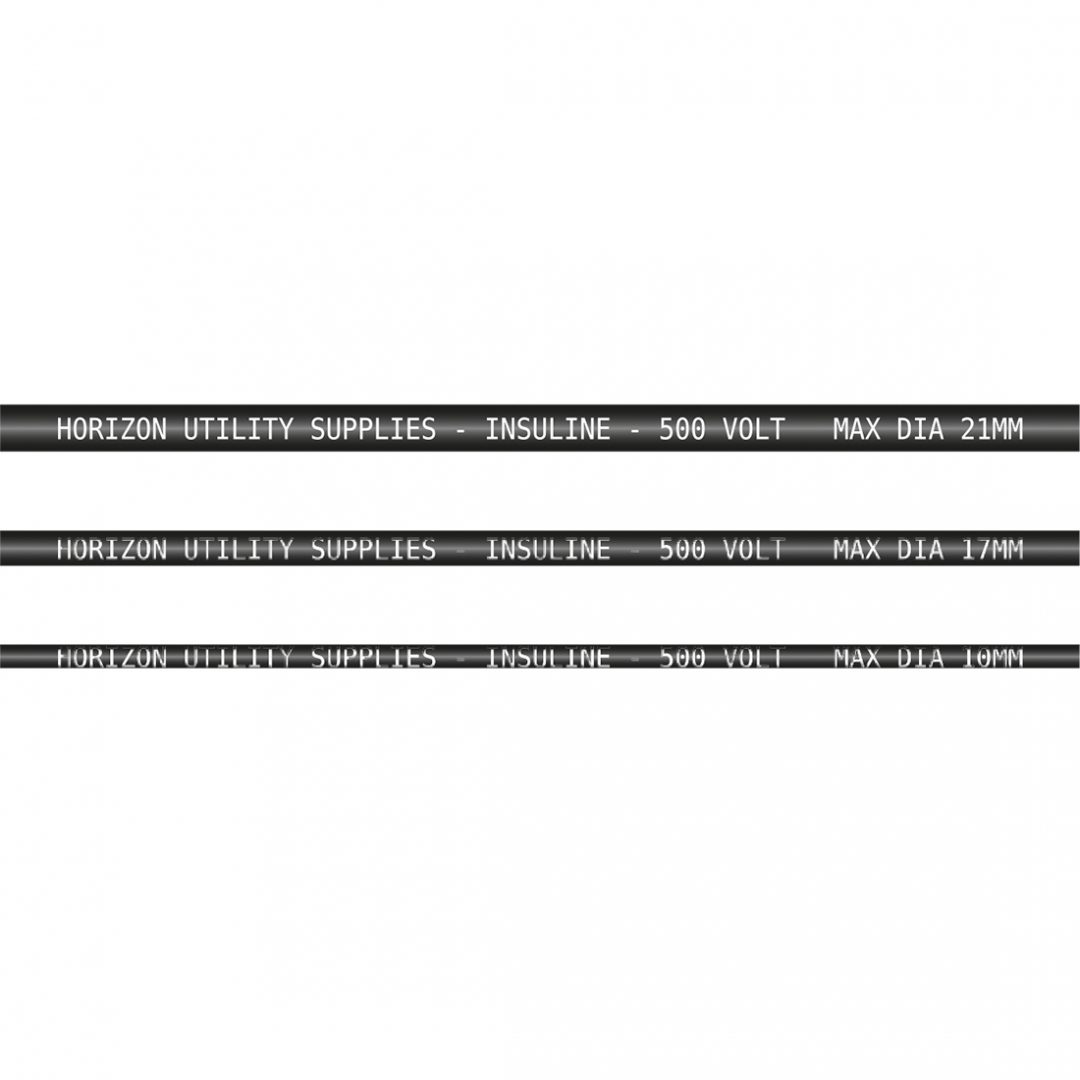

Available in 3 sizes (10mm, 17mm and 21mm diameter), Insuline overlaps on itself, fitting snugly onto the conductor and keeping the overall profile as close to the conductor size as possible, thus reducing the effects of wind and ice loading. It is manufactured in 3 metre lengths which, with the aid of a special tool, can be easily applied to the conductor.

Where required multiple lengths can be applied, overlapped and joined using approved UV stabilised electrical tape. Black in colour, Insuline will blend in to the environment unlike some shrouding products which are aesthetically unsuitable.

Testing

Insuline has been tested to and passed the relevant requirements of EATS 43-103 including Tensile Test, Puncture Test, Water Absorption Test, Artificial Ageing and Insulation Resistance Test, Electrical Breakdown Dry Test, Electrical Breakdown Prolonged Immersion Test and Flammability Test.

However, it was also deemed necessary to carry out further artificial ageing and resistance tests to prove the longevity of the product, and a two year program was set up in order to give some idea of the expected in-service life of the product. The basis for the further testing is summarised below in information provided to us by the testing authority.

“There is no definitive correlation between accelerated and natural weathering, even with areas such as Arizona that are considered to have reliable climate. Correlation depends on the material under test and the exact local climate and position. Even within the UK there is a vast difference between the South coast and the Lake District, for example, and from year to year. However, published data suggests acceleration factors of 10 to over 20, depending on material and other factors.”

It was proposed to carry out additional accelerated weathering and insulation resistance testing in 1200 hour segments, each of which would broadly represent 18 months’ to 3 years’ UK exposure. Eight test cycles have been successfully completed, which, using the criteria laid out above, represents 12 to 24 years’ UK exposure. This is the upper in-service product life requested by our existing customers.

Further, we have had Insuline installed on a trial line at a regional electricity company training school since 2007 with no visible signs of degradation. Additionally, Insuline has been tested at 10kV for 3 minutes without puncture.

Applications

With the pressing time limit for compliance to ESQCR regulations, Insuline offers a fast, cost effective, easy to install solution to the problem of providing insulation to existing LV overhead lines. Field experience now shows that installation of Insuline can have a positive effect on reducing outages caused by faults where trees grow in close proximity to LV lines. Insuline is also ideal for covering bare wire where the close proximity of steel lighting columns infringe safe working distances.